Table of Contents

Understanding Tractor Drawbars: A Technical Overview

- Definition and Functionality

Drawbars are the central attachment point on a tractor, enabling various implements and trailers to connect securely. By providing a stable, low point of attachment, they reduce tipping risks and distribute the load evenly. - Types of Drawbars

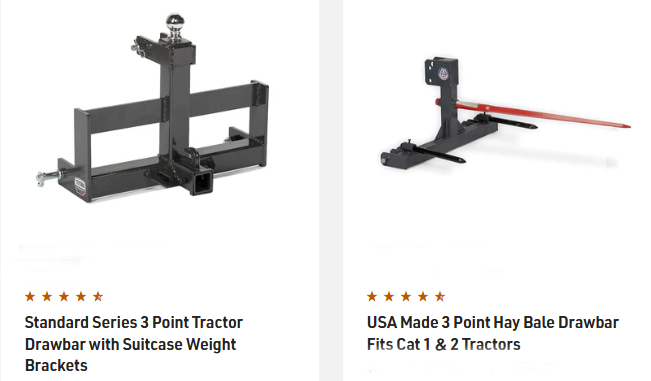

There are multiple types of drawbars, each designed for specific tasks:- Standard Drawbars: General-purpose drawbars suited for lighter loads and standard farming equipment.

- Swinging Drawbars: Allow lateral movement, ideal for equipment needing more flexibility, like hay balers or manure spreaders.

- 3-Point Hitch Drawbars: Used with 3-point hitch systems for maximum versatility, often paired with a quick hitch mechanism.

- Clevis Drawbars: Provide a highly stable connection, mainly used in heavier applications.

- Heavy-Duty Drawbars: Built for pulling heavy equipment, these have a higher weight capacity and are reinforced for durability.

Technical Specifications and Compatibility Considerations

- Load Capacity

The load capacity of drawbars varies based on their build and material. Farmers should check the maximum tongue weight and drawbar pull ratings to ensure compatibility with heavy equipment and safe operation. - Drawbar Length and Height

The length and height of a drawbar affect the turning radius and clearance. Longer drawbars provide greater turning freedom but can be harder to control with heavier loads. - Material and Coating

Drawbars are usually made from high-strength steel and coated with corrosion-resistant finishes to withstand tough agricultural conditions. - Compatibility with Tractor Models

Some drawbars are designed to be universal, while others are customized for specific brands or tractor models. Ensuring compatibility is key for seamless operations, especially with modern tractors equipped with precision technology.

Practical Maintenance Advice

- Regular Inspections

Farmers should inspect drawbars for cracks, bends, and rust. Structural damage can compromise safety, particularly under heavy loads. - Lubrication and Cleaning

Routine lubrication of joints and moving parts prevents wear. Cleaning drawbars after use removes debris that can lead to corrosion. - Bolt and Pin Checks

Bolts and pins are essential for a secure connection. Regularly tightening and replacing worn parts minimizes risk during operation.

Safety Precautions for Tractor Drawbar Use

- Load Limits

Exceeding the recommended load capacity is a primary cause of drawbar failure. Farmers should strictly adhere to weight limits for the tractor and attached implements. - Drawbar Height Adjustments

Improper height can result in instability, especially on uneven terrain. Adjusting the drawbar to the correct height for the implement helps reduce risk. - Attentiveness to Hitch Types

Using the correct hitch type for specific tasks is crucial. For instance, using a clevis hitch for a heavy load or a swinging drawbar for fieldwork can improve safety and performance.

Innovative Developments in Drawbar Technology

- Hydraulically Adjustable Drawbars

These drawbars allow real-time height adjustments from the tractor cab, enhancing control for various field conditions. - GPS and Precision Technology Integration

Advanced tractors are now equipped with GPS guidance systems that synchronize with drawbars, allowing for precise placement and alignment of implements. - Smart Drawbars

Emerging technology in sensor-equipped drawbars monitors load stress detects structural fatigue, and provides maintenance alerts, improving overall equipment longevity and operator safety.

Case Studies and Testimonials

- Case Study: John Deere 8R Series with Swinging Drawbar

In a recent upgrade, a midwestern farming cooperative adopted the John Deere 8R series tractors with swinging drawbars for hay baling. Farmers noted a 15% increase in productivity and smoother turns during baling, thanks to the drawbar’s flexibility. - Testimonial: Heavy-Duty Drawbars in Corn Farming

A Kansas corn farmer shares, “Switching to a heavy-duty clevis drawbar allowed me to haul larger loads with less stress on my tractor. It’s been a game-changer during peak harvest season.”

Future Trends and Potential Advancements in Drawbar Technology

- AI-Powered Predictive Maintenance

Predictive maintenance technology, already in use in some agricultural equipment, may soon extend to drawbars. AI systems could alert operators of potential stress points or upcoming maintenance needs. - Enhanced Materials and Coatings

New composite materials and nano-coatings might emerge to reduce wear further, increase load capacity, and resist corrosion. - Automated Adjustment Features

Fully automated height and angle adjustments could become standard, allowing farmers to manage implements without leaving the cab, reducing manual labor, and increasing operational efficiency.

Conclusion

Tractor drawbars play an indispensable role in agriculture, linking vital equipment and enabling a wide range of field tasks. Choosing the right drawbar type and following maintenance best practices can significantly impact farm productivity and safety. As technology evolves, tractor drawbars are poised to become even more sophisticated, offering features that boost efficiency and ease of use.