Table of Contents

As a farmer who’s spent decades in the fields, I’ve seen firsthand how proper tractor ballasting can make or break a season. Ballast boxes aren’t just add-ons – they’re essential tools for maximizing your tractor’s efficiency and protecting your soil.

Understanding Ballast Basics

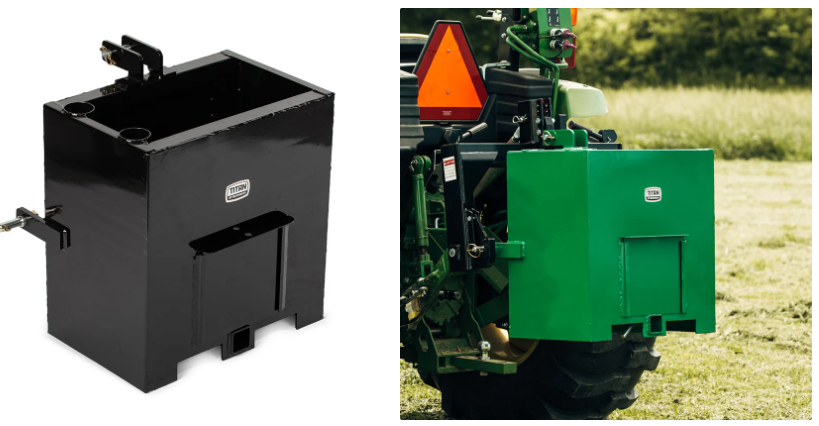

Ballast boxes are weight containers that attach to your tractor, typically at the rear. Their primary function is to optimize your tractor’s weight distribution for most performance and efficiency.

Think of your tractor as a complex machine where every component needs to work in harmony.

The engine, applies, and ballast all create weight at different points, and the ballast box helps balance it all out.

This balance is critical for several reasons:

- Traction: Additional weight on the drive wheels improves grip, especially in challenging conditions like wet or loose soil.

- Stability: Proper weight distribution keeps your tractor steady, reducing the risk of tipping, particularly on slopes or when making sharp turns.

- Fuel Efficiency: With improved traction, your engine doesn’t have to work as hard to move the tractor, leading to significant fuel savings.

- Implement Control: Balanced weight helps you maintain better control over attached applies, improving the quality of your fieldwork.

Keep in mind that ballasting isn’t a one-size-fits-all solution. The optimal setup varies based on your tractor model, the tasks you’re performing, and even the soil conditions you’re working with.

What works for spring plowing might not be ideal for summer mowing.

The Science of Soil Interaction

Many farmers worry that adding more weight to their tractor will increase soil compaction. However, proper ballasting can actually reduce soil compaction compared to an improperly balanced tractor.

Here’s why:

When a tractor is underballasted, it tends to slip more. This slipping action churns up the soil, causing more damage than the controlled pressure of a well-balanced machine.

A study by Iowa State University found that proper ballasting could reduce fuel consumption by up to 20% in certain field operations, partly because of reduced slippage.

However, there’s a delicate balance to strike. Overballasting can indeed lead to excessive compaction.

The key is finding the right balance for your specific needs, which often needs some trial and error in your own fields.

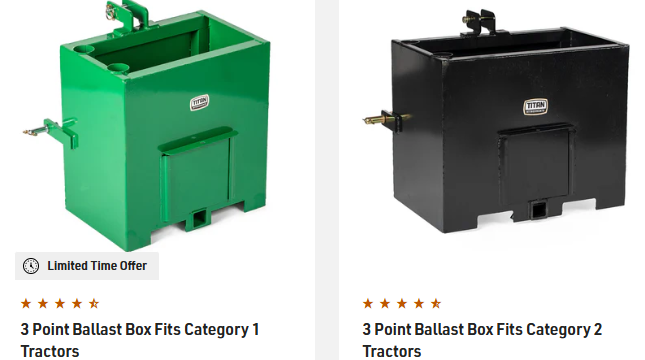

Here are the main types you’ll encounter:

- Fixed Weight Boxes: These are the simplest form, filled with a set amount of weight material, usually concrete or metal.

They’re cost-effective but lack flexibility.

- Adjustable Systems: These allow you to add or remove weight as needed. They’re more versatile but can be more time-consuming to adjust.

- Liquid Ballast: Some systems use water or other liquids for easy weight adjustment.

They’re great for fine-tuning but can be affected by temperature changes.

- Smart Ballast Systems: The newest technology on the block, these systems can automatically adjust weight distribution based on real-time data from sensors on the tractor.

They’re expensive but offer unparalleled precision.

When choosing a ballast box, consider not just your current needs, but future ones too. An adjustable system might cost more upfront but offer greater flexibility in the long run, especially if you’re planning to expand your operation or diversify your crops.

Implementing Your Ballast Strategy

Now that we’ve covered the basics, let’s get into the nitty-gritty of setting up your ballast box. Here’s a step-by-step guide:

- Assess Your Needs: Take a close look at your tractor’s specifications, the implements you use most often, and your typical field conditions.

Each of these factors will influence your optimal ballast setup.

- Calculate Optimal Weight: Use manufacturer guidelines or ballast calculators to decide the ideal weight distribution for your setup.

Many tractor manufacturers provide specific recommendations based on your model and common tasks.

- Choose Your Ballast Box: Select a system that meets your weight needs and offers the level of adjustability you require.

Consider factors like ease of installation, durability, and compatibility with your tractor model.

- Install Safely: Ensure the ballast box is securely attached according to manufacturer instructions.

Improper installation can be dangerous and may void your warranty.

- Test and Adjust: Start with the calculated weight, then test in field conditions.

Pay close attention to traction, fuel consumption, and overall performance.

Look for signs of slippage or excessive soil disturbance.

- Fine-Tune: Make small adjustments based on your observations.

You might need to add or remove weight, or shift the distribution between front and rear.

Remember, ballasting is as much an art as it is a science. What works perfectly in one field might need tweaking in another.

Don’t be afraid to experiment and trust your instincts as you get a feel for how your tractor performs under different conditions.

Common Ballasting Mistakes to Avoid

Even experienced farmers can fall into ballasting traps. Here are some common mistakes I’ve seen (and made myself) over the years:

- Overballasting: It’s tempting to think that if some weight is good, more must be better.

However, excessive weight can damage your tractor, increase fuel consumption, and cause unnecessary soil compaction.

- Ignoring Front-to-Rear Balance: Don’t focus solely on total weight.

The distribution between front and rear axles is crucial for stability and traction.

A general rule of thumb is to aim for 30% of the total weight on the front axle and 70% on the rear for most field operations.

- Set-and-Forget Mentality: Ballast needs change with different tasks and seasons.

What works for heavy tillage in spring might be overkill for lighter work in summer.

Regular reassessment is key to maintaining optimal performance year-round.

- Neglecting Tire Pressure: Proper inflation is crucial for effective weight distribution.

Overinflated tires reduce the contact patch with the ground, negating some of the benefits of proper ballasting.

- Mismatched Implements: Using implements that are too heavy or light for your ballast setup can negate it’s benefits.

Always consider the weight of your implements when adjusting your ballast.

- Overlooking Soil Conditions: Wet or loose soils might benefit from different weight distributions than firm ground.

Be prepared to adjust your ballast based on field conditions.

Adapting Your Ballast Strategy

Your ballasting needs will evolve with your farming operation. Here are some scenarios to consider:

- Seasonal Changes: You might need more weight for spring tillage than for summer mowing.

Create a seasonal ballasting plan to ensure you’re always optimized for the task at hand.

- New Implements: Each new attachment may need a ballast adjustment.

When investing in new equipment, factor in potential ballasting changes as part of your overall cost and setup considerations.

- Soil Conditions: Different soil types and moisture levels can significantly impact your tractor’s performance.

Develop a feel for how your tractor behaves in various conditions and be ready to adjust accordingly.

- Precision Farming: As you adopt more precise farming techniques, your ballasting strategy may need to become more nuanced. Smart ballast systems can integrate with GPS and yield mapping technology to optimize weight distribution in real-time across your fields.

- Changing Crop Rotations: If you’re diversifying your crops or changing your rotation, you may find that your ballasting needs shift. Be prepared to reassess and adjust as your farming practices evolve.

The goal is to have just enough weight to maximize efficiency without causing unnecessary compaction or strain on your equipment. It’s a delicate balance, but one that pays off in improved performance, reduced fuel costs, and better soil health.

Advanced Ballasting Techniques

Once you’ve mastered the basics, you can start exploring more advanced concepts:

- Dynamic Ballasting: This involves adjusting weight on-the-go for varying field conditions.

Some advanced systems allow you to shift weight between axles or even add or remove ballast without leaving the cab.

- Precision Weight Transfer: This technique involves fine-tuning weight distribution for specific implements and tasks.

For example, you might shift more weight to the rear when using a heavy plow, then redistribute it when switching to a lighter harrow.

- Integrated Ballast Systems: These advanced setups integrate ballasting with other tractor systems like hydraulics and GPS guidance.

They can automatically adjust weight distribution based on factors like implement draft, ground speed, and field position.

- Ballast Monitoring: Some modern tractors come equipped with sensors that continuously watch weight distribution and provide real-time feedback to the operator.

This allows for on-the-fly adjustments to maintain optimal performance.

- Custom Ballast Solutions: For specialized operations, you might consider working with an agricultural engineer to design a custom ballast system tailored to your specific needs and equipment.

Hands-On Exercises to Hone Your Skills

To truly master ballasting, you need hands-on experience. Here are some exercises I recommend:

- Ballast Audit: Assess your current setup.

Is it optimal for your most common tasks?

Document your current configuration, including total weight, distribution, and tire pressures.

- Slippage Test: Measure wheel slippage in different conditions with varying ballast.

Mark a set distance in your field and count wheel rotations.

Compare this to the theoretical number of rotations based on your tire size to calculate slippage percentage.

- Fuel Efficiency Challenge: Track fuel consumption over a week, then adjust your ballast and compare.

Keep detailed records of tasks performed, acreage covered, and fuel used to get an accurate comparison.

- Implement Matching: Practice quickly adjusting your ballast for different implements.

Time yourself and aim to reduce the adjustment period while maintaining accuracy.

- Soil Compaction Study: Use a penetrometer to measure soil compaction with different ballast setups.

Take readings at various depths and locations in your field to get a comprehensive picture of how your ballasting affects soil structure.

- Performance Mapping: Use GPS tracking to map your tractor’s performance across your fields with different ballast configurations.

Look for areas where performance drops and consider whether ballast adjustments could help.

The Future of Tractor Ballasting

As we look to the future, several exciting developments are on the horizon:

- AI-Driven Ballasting: Artificial intelligence could soon play a role in optimizing ballast in real-time, taking into account factors like soil conditions, implement draft, and even weather forecasts.

- Lightweight Materials: New, ultra-strong materials could change ballast box design, allowing for easier handling and more precise weight adjustments.

- Energy Storage Ballast: Some researchers are exploring the possibility of using heavy batteries as ballast, effectively combining weight distribution with energy storage for electric or hybrid tractors.

- Automated Implement Recognition: Future tractors might automatically detect attached implements and adjust ballast accordingly, streamlining the setup process.

- Soil Health Integration: Advanced sensors could watch soil health in real-time, allowing ballast systems to adjust to minimize compaction while maintaining optimal traction.

People Also Asked

What is the purpose of a ballast box on a tractor?

A ballast box adds weight to a tractor to improve traction, stability, and overall performance. It helps balance the weight distribution, especially when using heavy implements.

How much does a tractor ballast box weigh?

Tractor ballast boxes can weigh anywhere from a few hundred pounds to several thousand pounds, depending on the size of the tractor and the specific needs of the farmer.

Can you use water for tractor ballast?

Yes, water can be used as a liquid ballast in tractor tires or in specially designed liquid ballast boxes. It’s an economical option but can freeze in cold climates.

How do I know if my tractor needs more ballast?

Signs that your tractor needs more ballast include excessive wheel slip, poor fuel efficiency, difficulty controlling applies, and a tendency for the front end to lift during heavy pulling tasks.

What’s the difference between front and rear ballast on a tractor?

Front ballast helps counterbalance heavy rear-mounted implements and improves steering control. Rear ballast improves traction for pulling and helps prevent the front end from lifting during heavy tasks.

How often should I adjust my tractor’s ballast?

Ballast should be adjusted whenever you change implements or tasks, and potentially with seasonal changes in soil conditions. Some farmers adjust their ballast several times throughout the year.

Can proper ballasting improve fuel efficiency?

Yes, proper ballasting can significantly improve fuel efficiency by reducing wheel slip and ensuring the tractor operates at it’s optimal power range.

Is it possible to over-ballast a tractor?

Yes, over-ballasting can lead to excessive soil compaction, increased fuel consumption, and unnecessary wear on the tractor’s components. It’s important to find the right balance.

How does ballasting affect soil compaction?

Proper ballasting can actually reduce soil compaction by minimizing wheel slip. However, excessive ballast can increase compaction, especially in wet or loose soils.

Are there choices to traditional metal ballast boxes?

Yes, choices include liquid ballast systems, frame-mounted weight brackets, and even some advanced systems that use hydraulics to shift weight dynamically.

Key Takeaways

- Proper ballasting improves traction, stability, and fuel efficiency.

- The right ballast setup varies based on tractor, task, and conditions.

- Regular reassessment and adjustment of ballast is crucial for optimal performance.

- Advanced ballasting techniques can significantly enhance farming precision and efficiency.

- Hands-on experimentation is key to mastering the art and science of tractor ballasting.