Table of Contents

The Rise of Skid Steer Fork Frames

Construction sites, farms, and warehouses across the country are experiencing a quiet revolution in material handling. The catalyst for this change?

The humble skid steer fork frame.

These versatile attachments are transforming the capabilities of skid steer loaders, enabling businesses to streamline operations and boost productivity in ways before unimaginable.

Skid steer fork frames allow operators to easily switch between tasks, moving from earthmoving to precision material handling in a matter of minutes. This flexibility is proving invaluable across a wide range of industries, from construction and agriculture to landscaping and logistics.

The Evolution of Material Handling

The story of skid steer fork frames is rooted in practical innovation. When skid steer loaders first hit the market in the 1960s, they were primarily designed for excavation and pushing.

However, operators and engineers quickly recognized the potential for these agile machines to do much more.

The addition of fork frames was a natural progression, instantly expanding the functionality of skid steers. Early models were simple affairs, often custom-built by resourceful operators.

As demand grew, manufacturers began producing purpose-built attachments, leading to rapid advancements in design and capabilities.

Today’s skid steer fork frames are marvels of engineering. Constructed from high-strength steel alloys, they offer an impressive combination of durability and relatively lightweight.

Features like adjustable tine spacing allow operators to handle a wide variety of load sizes and shapes.

Some models even incorporate hydraulic positioning, enabling precise control from the comfort of the cab.

Versatility: The Key Advantage

The primary reason for the growing popularity of skid steer fork frames is their incredible versatility. Unlike traditional forklifts, which are limited to smooth, flat surfaces, skid steers can navigate rough terrain, tight spaces, and even moderate inclines with ease.

This adaptability makes skid steers with fork frames invaluable on construction sites, where conditions change rapidly and unpredictably. An operator might start the day unloading pallets of bricks, then transition to moving stacks of lumber across uneven ground, and finish by precisely placing heavy equipment – all with the same machine.

In agriculture, skid steer fork frames are changing material handling. Farmers use them to move everything from hay bales and seed pallets to livestock feed and harvested produce.

The compact size and maneuverability of skid steers allow for efficient operation in and around barns, greenhouses, and storage facilities.

Landscapers have embraced skid steer fork frames for their ability to handle a wide range of materials. From moving trees and shrubs to placing decorative boulders, these attachments provide the precision and power needed for both large-scale projects and intricate garden designs.

Even in warehousing and logistics, where traditional forklifts have long reigned supreme, skid steers with fork frames are finding a niche. Their ability to operate in tight spaces and on varied surfaces makes them ideal for outdoor storage yards and facilities with mixed indoor/outdoor operations.

Maximizing Efficiency Across Industries

The impact of skid steer fork frames extends far beyond their immediate material handling capabilities. By eliminating the need for many specialized machines, businesses can significantly reduce their equipment costs and simplify their operations.

In construction, a single skid steer with the right attachments can replace several dedicated machines. This reduces initial investment costs lowers ongoing maintenance expenses and simplifies operator training.

The versatility of skid steers with fork frames allows construction companies to be more agile, quickly adapting to changing project requirements without the need to rent or purchase additional equipment.

Agricultural operations benefit from the year-round utility of skid steers with fork frames. During the planting season, they can be used to move seed and fertilizer.

Come harvest time, the same machine can handle crops and assist with storage.

In between, it’s available for general farm maintenance and material handling tasks. This multi-functionality is especially valuable for small to medium-sized farms where equipment budgets are often tight.

Landscaping businesses find that skid steer fork frames allow them to take on a wider range of projects. The ability to easily switch between digging, grading, and material handling attachments means landscapers can offer more comprehensive services to their clients.

This versatility can be a significant competitive advantage in a crowded market.

In warehousing and logistics, the introduction of skid steers with fork frames is enabling new approaches to space utilization. Their compact size and maneuverability allow for narrower aisles and tighter storage configurations, potentially increasing the usable space within a facility.

For operations with both indoor and outdoor storage areas, the ability to use a single machine across varied terrain can significantly improve efficiency.

Overcoming Challenges and Maximizing Potential

While skid steer fork frames offer numerous advantages, they also present some challenges that operators and businesses must address to maximize their potential.

Compatibility issues between different skid steer models and attachment brands can sometimes arise. It’s crucial to carefully research and select fork frames that are compatible with your specific skid steer model.

Many manufacturers offer universal mounting systems, but it’s always best to verify compatibility before making a purchase.

Safety is another critical consideration when using skid steer fork frames. While these attachments enhance the capabilities of a skid steer, they also introduce new safety considerations that operators must be trained to address.

Proper load balancing, visibility awareness, and understanding of the machine’s altered center of gravity are all essential skills for safe operation.

To maximize the potential of skid steer fork frames, investing in comprehensive operator training is crucial. This confirms safe operation and helps unlock the full productivity benefits these attachments offer.

Many equipment manufacturers and industry organizations offer specialized training programs focused on the effective and safe use of skid steer attachments.

Regular maintenance is also key to getting the most out of your skid steer fork frame. Daily inspections of the attachment, mounting system, and hydraulic connections can help prevent unexpected downtime and extend the life of both the attachment and the skid steer itself.

The Future of Material Handling with Skid Steer Fork Frames

As we look to the future, the potential for skid steer fork frames continues to expand. Innovations in materials science are leading to the development of lighter yet stronger frames, improving payload capacity without sacrificing durability.

The integration of smart technologies and IoT capabilities is opening up new possibilities for remote operation and predictive maintenance. Here’s a construction site where skid steers with fork frames autonomously move materials to where they’re needed, guided by real-time project data and AI algorithms.

While fully autonomous operation may still be a few years away, semi-automated systems are already being tested in controlled environments.

Advancements in hydraulic systems are also improving the precision and control of skid steer fork frames. Some manufacturers are developing attachments with integrated sensors that can detect load weight and automatically adjust the machine’s settings for optimal performance and safety.

Environmental concerns are driving the development of electric and hybrid skid steers, which will likely lead to new design considerations for attachments like fork frames. These eco-friendly machines could open up new applications in indoor spaces and noise-sensitive environments.

Practical Tips for Implementation

If you’re considering adding a skid steer fork frame to your equipment arsenal, here are some key points to keep in mind:

Assess Your Specific Needs

Take the time to carefully evaluate the types of materials you’ll be handling, the terrain you’ll be working on, and the frequency of use. This will help you select the right capacity and features for your fork frame attachment.

Ensure Compatibility

Not all attachments work with all machines, so do your homework before making a purchase. Check with both your skid steer manufacturer and potential attachment suppliers to confirm compatibility.

Invest in Quality

While it might be tempting to opt for a cheaper option, remember that this attachment will be handling heavy loads in potentially challenging conditions. A well-built fork frame will pay for itself in durability, reliability, and improved productivity.

Prioritize Safety

Make sure all operators receive proper training on the safe use of the attachment, including load capacity limits, proper maneuvering techniques, and visibility considerations. Develop and enforce clear safety protocols for all material handling operations.

Consider Future Needs

If your business is growing, it might be worth investing in a more versatile or higher-capacity attachment that can grow with you. Consider attachments with adjustable features or the ability to add accessories later.

Achieving Proficiency in the Art of Material Handling

As you become more proficient with your skid steer fork frame, you’ll start to see opportunities for efficiency gains that you might have missed before. Maybe it’s a new way to stack materials that saves space, or a more effective route through your job site that cuts down on travel time.

The key is to stay curious and always be looking for ways to improve. Talk to other operators, attend industry trade shows, and keep an eye on emerging technologies.

Share best practices within your organization and encourage a culture of continuous improvement.

Exercises to Enhance Your Skills

To master the use of skid steer fork frames, practice is key. Here are a few exercises you can try to hone your skills:

Precision Placement

Set up a series of targets and practice placing pallets or other loads as accurately as possible. Time yourself to add an element of pressure.

This exercise helps develop the fine control needed for precise material placement in tight spaces.

Obstacle Course

Create a course with various obstacles and practice maneuvering through it with a load. This will help improve your skills in tight spaces and simulate real-world conditions you might encounter on a job site.

Load Balancing

Practice picking up and moving loads of different sizes and weights. Focus on maintaining stability and control throughout the movement.

This exercise helps develop a feel for how different loads affect the machine’s balance and handling.

Speed Runs

Set up a simple course and time yourself moving a load from point A to point B. Try to improve your time while maintaining safety and control.

This helps develop efficiency in repetitive tasks like loading trucks or moving materials across a job site.

Team Challenge

If you work with others, set up relay races or other team-based challenges to make training more engaging and foster a spirit of friendly competition. This can help improve coordination between operators and other team members.

Remember, the goal of these exercises isn’t just to get faster – it’s to develop a deeper understanding of how your skid steer and fork frame attachment work together. With practice, you’ll develop an intuitive feel for the machine that will serve you well in real-world applications.

Industry-Specific Applications

Construction

In the construction industry, skid steer fork frames shine in material distribution tasks. They excel at moving pallets of bricks, lumber, and other building materials around job sites.

Their compact size allows them to navigate through partially constructed buildings, making them invaluable for interior work.

Skid steers with fork frames also play a crucial role in site preparation and cleanup. They can easily move erosion control materials, transport small equipment, and assist with waste removal.

Their versatility means they’re rarely idle on a construction site, contributing to improved overall project efficiency.

Agriculture

Farmers find skid steer fork frames indispensable for a wide range of tasks. During planting season, they’re used to move seed pallets, fertilizer bags, and other inputs.

At harvest time, they assist with moving harvested crops, especially in operations where produce is packed in the field.

In livestock operations, skid steers with fork frames are used to move feed, bedding materials, and even small equipment. Their maneuverability makes them ideal for working in and around barns and other farm structures.

Landscaping

Landscapers use skid steer fork frames for everything from unloading trucks to placing large plants and trees. They’re particularly useful for moving and placing hardscaping materials like pavers, retaining wall blocks, and decorative boulders.

In nursery operations, skid steers with fork frames are used to move potted plants, bags of soil and mulch, and other materials. Their ability to work on unpaved surfaces makes them ideal for navigating through growing areas and outdoor storage yards.

Warehousing and Logistics

While traditional forklifts still dominate in many warehouses, skid steers with fork frames are finding niches in mixed indoor/outdoor operations. They’re particularly useful in lumber yards, building supply centers, and other businesses that need to move materials between indoor storage and outdoor loading areas.

In recycling and waste management facilities, skid steers with fork frames are used to move bales of recycled materials, load trucks, and assist with general material handling tasks. Their durability and ability to work in challenging conditions make them well-suited for these environments.

Maintenance and Care

Proper maintenance is crucial for getting the most out of your skid steer fork frame. Here are some key maintenance tasks to keep in mind:

Daily Inspections

Before each use, visually inspect the fork frame for any signs of damage or wear. Check for loose bolts, cracks in welds, and any deformation of the frame or tines.

Ensure that all hydraulic connections are secure and free from leaks.

Lubrication

Regularly lubricate all moving parts according to the manufacturer’s recommendations. This typically includes pivot points, adjustable mechanisms, and any hydraulic cylinders.

Hydraulic System Care

Keep the hydraulic system clean and well-maintained. Regularly check hydraulic fluid levels and change the fluid and filters according to the skid steer manufacturer’s guidelines. Contaminated hydraulic fluid can cause premature wear on both the attachment and the machine.

Tine Maintenance

Inspect the fork tines regularly for wear, bending, or other damage. Bent or excessively worn tines can affect load stability and should be repaired or replaced promptly.

Some fork frames allow for line replacement, which can be a cost-effective way to extend the life of the attachment.

Storage

When not in use, store the fork frame in a clean, dry area. If possible, store it off the ground to prevent moisture damage.

Consider applying a light coat of rust-preventative oil to exposed metal surfaces if the attachment will be stored for an extended period.

Documentation

Keep detailed records of all maintenance performed on the fork frame. This can help identify patterns of wear or damage and confirm that regular maintenance tasks are not overlooked.

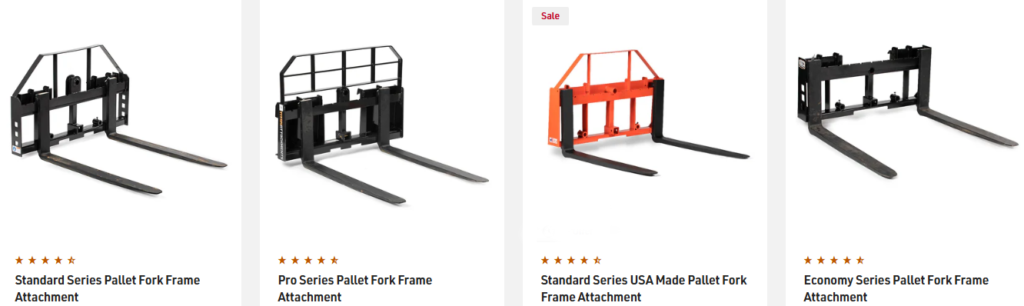

Selecting the Right Skid Steer Fork Frame

Choosing the right skid steer fork frame for your needs involves considering several factors:

Load Capacity

Determine the most weight you’ll need to lift and choose a fork frame rated for that capacity. Remember to factor in the weight of the attachment itself when calculating your skid steer’s total lift capacity.

Fork Length

Consider the types of loads you’ll be handling most often. Longer forks may be necessary for oversized loads, while shorter forks can provide better maneuverability in tight spaces.

Adjustability

Some fork frames offer adjustable tine spacing, which can be valuable if you handle a variety of load sizes. Consider whether this feature would be beneficial for your operations.

Visibility

Look for designs that offer good visibility through the frame. This is crucial for safe and efficient operation, especially when working with smaller or irregularly shaped loads.

Durability

Consider the construction of the frame. High-strength steel and quality welding are important for longevity, especially in demanding applications.

Compatibility

Ensure that the fork frame is compatible with your specific skid steer model. Check both the mounting system and hydraulic requirements.

Additional Features

Some fork frames offer extra features like hydraulic positioning, integrated load backrests, or the ability to add accessories. Evaluate whether these features would enhance your operations.

Training and Safety Considerations

Proper training is essential for safe and effective use of skid steer fork frames. Key areas to cover in operator training include:

Load Handling

Operators should understand proper techniques for picking up, transporting, and placing loads. This includes assessing load stability, maintaining proper load distribution, and understanding the skid steer’s load capacity limits.

Visibility Awareness

Using a fork frame can affect an operator’s field of view. Training should cover techniques for maintaining visibility, including proper positioning of the attachment and use of spotters when necessary.

Terrain Navigation

Operators need to understand how different terrains affect the stability and handling of a skid steer with a loaded fork frame. This includes navigating slopes, uneven surfaces, and transitions between different surface types.

Attachment Mounting

Proper mounting and dismounting of the fork frame attachment is crucial for safety. Training should cover the correct procedures for attaching and detaching the apply, including verifying secure connections.

Maintenance Checks

Operators should be trained to perform daily inspections of both the skid steer and the fork frame attachment. This includes checking for wear, damage, and proper lubrication.

Emergency Procedures

Training should cover procedures for handling potential emergencies, such as hydraulic failures or tip-overs.

Environmental Considerations

As sustainability becomes an increasingly important consideration in equipment selection, it’s worth noting the potential environmental benefits of using skid steers with fork frames:

Reduced Fleet Size

The versatility of skid steers with interchangeable attachments can allow businesses to maintain smaller equipment fleets. This can lead to reduced overall fuel consumption and lower emissions.

Improved Efficiency

The maneuverability and adaptability of skid steers can lead to more efficient operations, potentially reducing fuel consumption and emissions compared to using many specialized machines.

Electric Options

As mentioned earlier, electric skid steers are becoming more common. When paired with fork frames, these machines offer zero-emission material handling capabilities, which can be particularly valuable for indoor operations or in environmentally sensitive areas.

Reduced Site Impact

The compact size and maneuverability of skid steers can result in less ground disturbance compared to larger equipment, which can be beneficial in sensitive environments or when working on finished surfaces.

Frequently Asked Questions

What is a skid steer fork frame?

A skid steer fork frame is an attachment that converts a skid steer loader into a forklift-like machine, allowing it to lift and transport palletized materials and other heavy loads.

How much weight can a skid steer forkframe lift?

The lifting capacity varies depending on the specific skid steer model and fork frame attachment. Typical capacities range from 1,000 to 5,000 pounds, but some heavy-duty models can lift even more.

Can any skid steer use a fork frame attachment?

Most modern skid steers can use fork frame attachments, but it’s important to verify compatibility with your specific model. Factors like hydraulic flow requirements and mounting systems need to be considered.

Are skid steer fork frames adjustable?

Many skid steer fork frames offer adjustable tine spacing to accommodate different load sizes. Some models also feature hydraulic positioning for added versatility.

How do skid steer fork frames compare to traditional forklifts?

Skid steers with fork frames are generally more versatile and can operate on rougher terrain than traditional forklifts. However, they typically have lower lift heights and capacities compared to dedicated forklifts.

What industries commonly use skid steer fork frames?

Skid steer fork frames are widely used in construction, agriculture, landscaping, and material handling industries. They’re also gaining popularity in warehousing and logistics operations.

How much does a skid steer fork frame cost?

Prices for skid steer fork frames can range from about $1,000 for basic models to $5,000 or more for heavy-duty or specialized attachments. Factors like capacity, features, and brand influence the price.

Can skid steer fork frames be used for snow removal?

While not their primary purpose, some operators use fork frames to move large chunks of ice or compacted snow in winter maintenance operations. However, dedicated snow removal attachments are generally more effective for this task.

How often should a skid steer fork frame be inspected?

Daily visual inspections are recommended before each use. More thorough inspections and maintenance should be performed according to the manufacturer’s guidelines, typically at regular intervals or after a certain number of operating hours.

Can skid steer fork frames be used to lift people?

No, skid steer fork frames should never be used to lift people. This is extremely dangerous and violates safety regulations.

Only use approved personnel lifts or aerial work platforms for elevating workers.

Key Takeaways

- Skid steer fork frames significantly enhance the versatility of skid steer loaders, enabling efficient material handling across various industries.

- These attachments offer advantages in construction, agriculture, landscaping, and warehousing operations because of their adaptability and maneuverability.

- Proper training and safety protocols are essential for maximizing the benefits of skid steer fork frames while minimizing risks.

- Regular maintenance and careful selection of the right attachment for your needs are crucial for long-term success with skid steer fork frames.

- The future of skid steer fork frames includes potential advancements in materials, smart technologies, and eco-friendly designs.