Table of Contents

Introduction

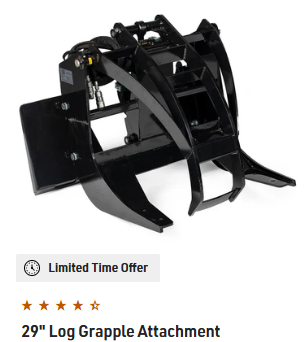

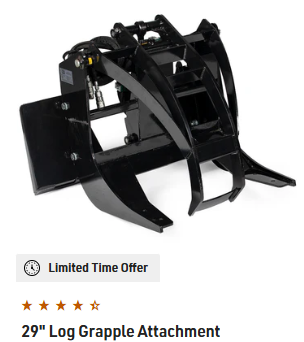

Skid steer log grapples improve your basic skid steer into a powerful logging machine. These attachments excel at handling logs and brushes, making them invaluable for both professional loggers and property owners tackling land-clearing projects.

In this comprehensive guide, we’ll explore everything from selecting the ideal grapple to advanced techniques that will elevate your logging efficiency.

The Anatomy of a Log Grapple

Understanding the key components of a log grapple is essential for maximizing it’s potential. Let’s break down the crucial elements:

Jaws of Steel

The jaws form the core of any log grapple. Crafted from high-strength steel, these opposing arms provide the gripping power necessary for handling heavy logs and debris.

Jaw designs vary, with some featuring straight edges for a firm hold on uniform logs, while others incorporate curved profiles to better cradle irregularly shaped materials.

Hydraulic System

A robust hydraulic system powers the grapple’s jaws, enabling it to lift logs weighing thousands of pounds. The hydraulic cylinders are engineered for both power and precision, allowing operators to maneuver logs delicately in tight spaces or lift heavy loads with ease.

Rotator Assembly

Many modern grapples include a rotator, enabling 360-degree rotation. This feature dramatically increases versatility, making it easier to position logs and navigate obstacles in challenging terrain.

Quick-Attach System

A universal quick-attach system is crucial for maximizing the utility of your skid steer. This feature allows you to swap out your grapple for other attachments in minutes, enhancing the overall flexibility of your equipment.

Choosing the Right Grapple

Selecting the perfect log grapple for your skid steer requires careful consideration of several factors:

Size Considerations

Grapple size is typically measured by the jaw opening, which can range from 30 to 60 inches or more. While larger grapples can handle bigger logs, they may also be heavier and less maneuverable.

Consider the average size of the logs you’ll be handling and choose a grapple that strikes the right balance between capacity and maneuverability.

Weight Capacity

Every skid steer has the most lifting capacity, and your grapple should be chosen with this in mind. Overloading your machine can lead to instability and potential accidents.

Always choose a grapple that leaves some room for your skid steer’s lifting capacity to ensure safe and efficient operation.

Fixed vs. Rotator Grapples

While rotator grapples offer increased versatility, they also come with a higher price tag and more complex hydraulics. If you’re primarily working in open areas with straightforward log extraction, a fixed grapple might suffice.

However, for operations in tight spaces or on uneven terrain, the added maneuverability of a rotator can be invaluable.

Tooth Design

The design of the grapple’s teeth significantly impacts its performance. Some grapples feature replaceable teeth, which can be a cost-effective option for long-term maintenance.

Others incorporate a solid edge design, which may be more suitable for handling delicate materials or working in environmentally sensitive areas.

Mastering Grapple Techniques

Now that we’ve covered the basics, let’s explore some advanced techniques that will help you get the most out of your log grapple:

The Pivot Pick

The pivot pick technique is invaluable when dealing with long logs. Instead of attempting to lift the entire log at once, use the grapple to grab one end and lift it slightly.

Then, use the skid steer’s momentum to pivot the log, allowing you to reposition the grapple closer to the center of gravity for a more balanced lift.

The Brush Sweep

Clearing brush and small debris can be time-consuming, but the brush sweep technique can significantly speed up the process. Open the grapple wide and use it like a giant rake, sweeping across the ground to gather smaller materials into a pile.

Once you’ve accumulated enough, close the grapple and lift the entire bundle at once.

The Log Roll

When you encounter a log that’s too heavy to lift, the log roll technique comes in handy. Position the grapple at one end of the log, close it securely, and then use the skid steer’s motion to roll the log along the ground.

This method allows you to move massive logs with minimal strain on your equipment.

The Precision Stack

Building neat log piles is crucial for effective processing and transportation. Use the grapple’s rotator (if equipped) to carefully align each log as you stack.

Start with larger logs at the base and work your way up, using the grapple to gently nudge each log into place for a stable and efficient pile.

Overcoming Common Challenges

Even with the right equipment and techniques, you’re bound to encounter obstacles in the field. Here are some common challenges and strategies to overcome them:

Slippery Conditions

Wet or muddy conditions can make log handling treacherous. To maintain control, reduce your speed and use the grapple to stabilize the load as you move.

Consider adding tire chains or tracks to your skid steer for improved traction in challenging terrain.

Uneven Terrain

Working on slopes or uneven ground requires extra caution. Always position your skid steer perpendicular to the slope when lifting, and use the grapple to help balance the load.

If possible, create temporary level platforms for more stable operation.

Oversized Logs

When faced with a log that exceeds your grapple’s capacity, don’t try to force it. Instead, use a chainsaw to cut the log into manageable sections.

Alternatively, consider using many attachment points, such as combining your grapple with a winch, to distribute the load safely.

Environmental Protection

Minimizing soil disturbance is crucial for responsible forest management. Use your grapple to lift logs clear of the ground when moving them, rather than dragging them.

This reduces soil compaction and helps preserve the forest floor.

Emerging Technologies in Log Grapple Design

The field of log grapple technology is constantly evolving. Here are some exciting developments to keep an eye on:

Smart Grapples

Manufacturers are developing grapples equipped with sensors and AI-driven control systems. These smart grapples can sense the weight and shape of a log, automatically adjusting their grip for optimal handling.

This technology promises to increase efficiency and reduce operator fatigue.

Eco-Friendly Materials

As environmental concerns grow, manufacturers are exploring new materials for grapple construction. High-strength, lightweight alloys could reduce the overall weight of grapples, allowing for larger capacities without compromising skid steer performance.

Integrated Cameras and Sensors

Advanced vision systems and proximity sensors may soon become standard on high-end grapples. These features will provide operators with enhanced visibility and prevent accidental collisions or damage to valuable timber.

Hybrid Attachments

The line between different forestry attachments is blurring. Manufacturers are developing hybrid tools that combine the functions of grapples, buckets, and even mulchers.

These versatile attachments could dramatically reduce the need for equipment swaps on job sites.

Maintenance and Care for Your Log Grapple

Proper maintenance is crucial for ensuring the longevity and performance of your log grapple. Here are some essential tips:

Daily Inspections

Before each use, visually inspect your grapple for any signs of wear, damage, or loose components. Pay particular attention to hydraulic hoses, fittings, and cylinders for any leaks or damage.

Lubrication

Regularly grease all pivot points and moving parts according to the manufacturer’s recommendations. This reduces friction, prevents premature wear, and confirms smooth operation.

Hydraulic System Care

Monitor hydraulic fluid levels and quality regularly. Replace filters as recommended by the manufacturer, and address any leaks promptly to prevent contamination and system damage.

Teeth and Cutting Edge Maintenance

For grapples with replaceable teeth, inspect them regularly and replace worn or damaged teeth promptly. For solid edge grapples, periodically check for wear and have the edge rebuilt or replaced as needed.

Winter Storage

If you’re storing your grapple for an extended period, clean it thoroughly and apply a coat of rust-preventative to exposed metal surfaces. Store the grapple in a dry, covered area to protect it from the elements.

Safety Considerations

Operating a skid steer with a log grapple attachment requires a strong focus on safety. Here are some critical safety guidelines to follow:

Personal Protective Equipment (PPE)

Always wear appropriate PPE, including a hard hat, safety glasses, hearing protection, and steel-toed boots. When operating in areas with potential falling debris, consider using a face shield for extra protection.

Machine Stability

Be aware of your skid steer’s center of gravity, especially when lifting heavy logs. Avoid sudden movements or sharp turns while carrying a load, and always travel with the load as low to the ground as possible.

Load Limits

Never exceed the rated lifting capacity of your skid steer or grapple. Overloading can lead to tipping, equipment damage, or hydraulic failure.

Pinch Points

Be mindful of pinch points created by the grapple’s moving parts. Keep hands and feet clear of these areas during operation, and ensure bystanders maintain a safe distance.

Communication

When working with a team, establish clear hand signals or radio communication protocols to coordinate movements and avoid accidents.

Environmental Considerations

Responsible logging practices are essential for maintaining healthy forests and ecosystems. Here are some key environmental considerations when using log grapples:

Minimizing Soil Disturbance

Use your grapple to lift logs clear of the ground whenever possible, rather than dragging them. This helps preserve the forest floor and reduces soil compaction.

Protecting Remaining Trees

Be careful not to damage remaining trees when maneuvering logs. Use the grapple’s precision to navigate tight spaces without causing unnecessary harm to surrounding vegetation.

Managing Debris

Use your grapple to collect and properly dispose of logging debris. This can help reduce fire hazards and promote healthy forest regeneration.

Wetland and Waterway Protection

Take extra care when working near wetlands or waterways. Use your grapple to keep logs and debris out of these sensitive areas to protect water quality and aquatic habitats.

Maximizing Productivity with Your Log Grapple

To get the most out of your log grapple, consider these productivity-boosting tips:

Efficient Log Sorting

Use your grapple to sort logs by size or species as you work. This can save time during processing and transportation.

Strategic Pile Placement

Plan your log pile locations carefully. Position piles in easily accessible areas that minimize travel time and maximize efficiency for the next stage of your operation.

Multitasking

If your skid steer is equipped with a rotator grapple, use it to perform many tasks without changing attachments. For example, you can use it to clear brush, stack logs, and load trucks all with the same tool.

Continuous Improvement

Regularly assess your techniques and look for ways to streamline your processes. Small efficiency improvements can add up to significant time and cost savings over time.

Choosing the Right Skid Steer for Grapple Work

While this guide focuses on log grapples, it’s worth noting that the skid steer itself plays a crucial role in your logging operation’s success. Here are some factors to consider when selecting a skid steer for grapple work:

Hydraulic Flow and Pressure

Ensure your skid steer has sufficient hydraulic flow and pressure to power your grapple effectively. High-flow hydraulics can provide faster cycle times and improved performance.

Lift Capacity

Choose a skid steer with a lift capacity that exceeds your typical log weights. This provides a margin of safety and allows you to handle larger logs when needed.

Stability

Look for a skid steer with a wide stance and low center of gravity for improved stability when handling heavy loads.

Visibility

Good visibility is crucial for safe and efficient grapple operation. Consider models with large windows, backup cameras, and other visibility-enhancing features.

Comfort and Controls

Since logging operations often involve long hours, choose a skid steer with a comfortable cab and intuitive controls to reduce operator fatigue.

Advanced Logging Strategies

As you become more proficient with your log grapple, consider incorporating these advanced strategies into your operations:

Selective Harvesting

Use your grapple’s precision to remove specific trees while minimizing damage to surrounding vegetation carefully. This technique is valuable for sustainable forestry practices and habitat management.

Winching Assistance

In challenging terrain, combine your grapple with a winch to extract logs from hard-to-reach areas. The grapple can then be used to organize and stack the winched logs efficiently.

Processing in Place

For operations with on-site processing equipment, use your grapple to feed logs directly into chippers or processors. This can significantly streamline your workflow and reduce the need for extra handling equipment.

Brush Management

Utilize your grapple for effective brush management by gathering and piling slash for later disposal or processing. This can help reduce fire hazards and promote healthy forest regeneration.

The Future of Logging with Grapples

As technology continues to advance, the future of logging with grapples looks promising. Here are some potential developments on the horizon:

Autonomous Operations

While fully autonomous logging is still a ways off, we may see semi-autonomous features that assist operators in repetitive tasks or help navigate difficult terrain.

Augmented Reality Displays

Heads-up displays could provide operators with real-time information about log weights, machine stability, and optimal grapple positioning.

Eco-Friendly Power Sources

As the industry moves towards more sustainable practices, we may see the development of electric or hybrid skid steers with powerful enough hydraulics to operate log grapples effectively.

Biomass Utilization

Advanced grapple designs could facilitate more efficient collection and processing of logging residues for biomass energy production, turning waste into a valuable resource.

Frequent Questions People Also Asked

What size log grapple do I need for my skid steer?

The size of the log grapple you need depends on your skid steer’s lifting capacity and the typical size of logs you’ll be handling. Generally, a grapple with a jaw opening between 30-60 inches works well for most applications.

How much does a skid steer log grapple cost?

Skid steer log grapple prices vary widely based on size, features, and quality. Basic models start around $2,000, while high-end grapples with rotators can cost $10,000 or more.

Can I use a log grapple for brush clearing?

Yes, log grapples are excellent for brush clearing. The wide jaw opening allows you to gather large amounts of brush and small trees efficiently.

What’s the difference between a log grapple and a root grapple?

Log grapples are designed specifically for handling logs and typically have smoother jaws. Root grapples often have more aggressive teeth for digging and are better suited for tasks like land clearing and stump removal.

How do I maintain my skid steer log grapple?

Regular maintenance includes greasing pivot points, checking hydraulic connections for leaks, inspecting teeth or cutting edges for wear, and addressing any structural issues promptly.

Can I use a log grapple on frozen ground?

Yes, log grapples can be used on frozen ground. However, extra caution is needed because of reduced traction.

Consider using tire chains or tracks on your skid steer for better stability.

What safety precautions should I take when using a log grapple?

Key safety measures include wearing proper PPE, maintaining a clear work area, being aware of load limits and machine stability, and never operating under suspended loads.

How do I choose between a fixed and rotating grapple?

Consider your work environment and typical tasks. Rotating grapples offer more versatility and are better for tight spaces, while fixed grapples are simpler and often less expensive.

Can log grapples damage trees I’m not harvesting?

If used carelessly, log grapples can damage surrounding trees. Proper technique and careful maneuvering are essential to minimize unintended damage during logging operations.

What’s the largest log a skid steer grapple can handle?

The log size depends on your skid steer’s lifting capacity and the grapple’s design. Some larger grapples can handle logs up to 36 inches in diameter, but always check your equipment’s specifications.

Key Takeaways

- Choose a grapple that matches your skid steer’s capabilities and specific logging needs.

- Master advanced techniques like the pivot pick and brush sweep to increase efficiency.

- Adapt your approach to overcome challenges like wet conditions and uneven terrain.

- Stay informed about emerging technologies that could change log grapple operations.

- Prioritize environmental protection and sustainable logging practices in all your operations.